Pickling and phosphating aggregates

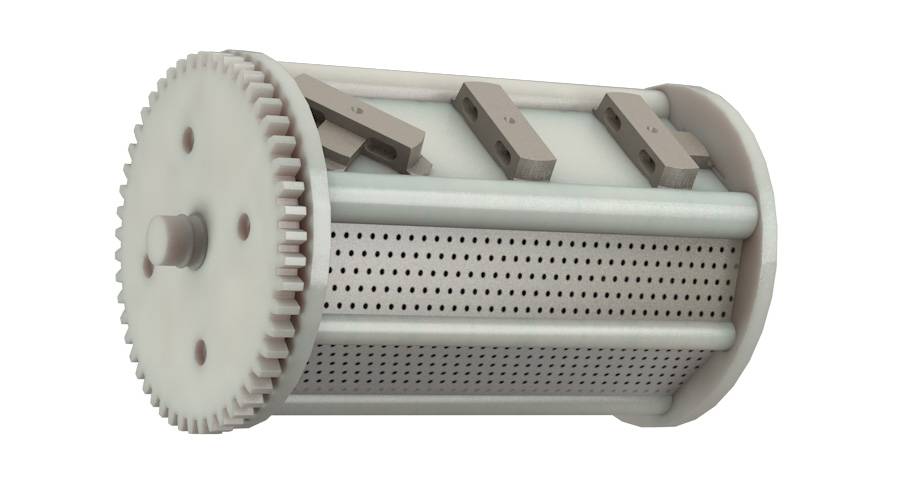

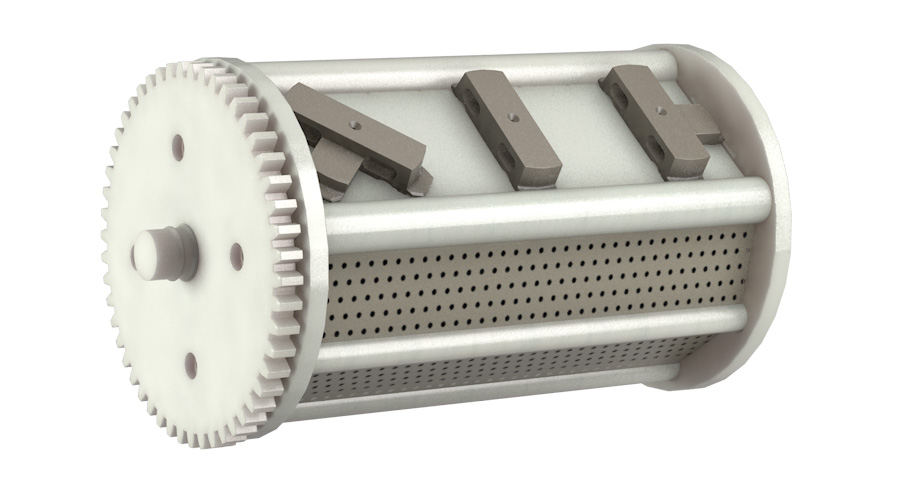

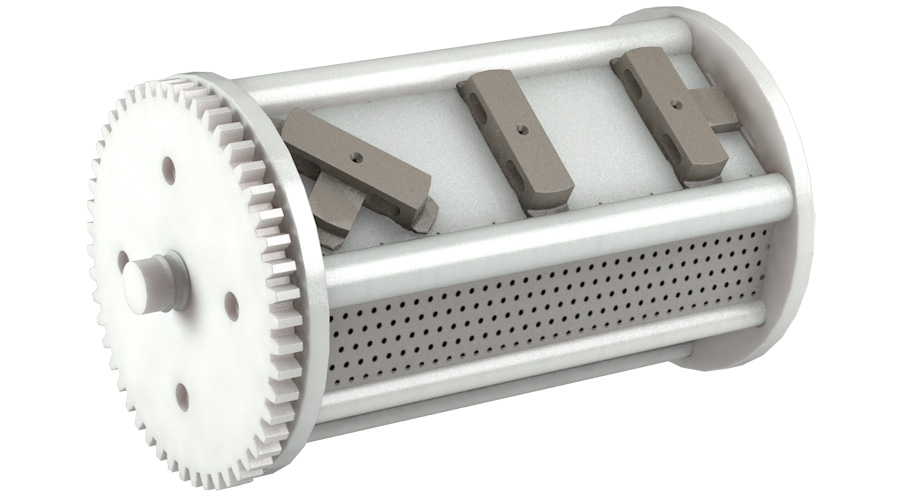

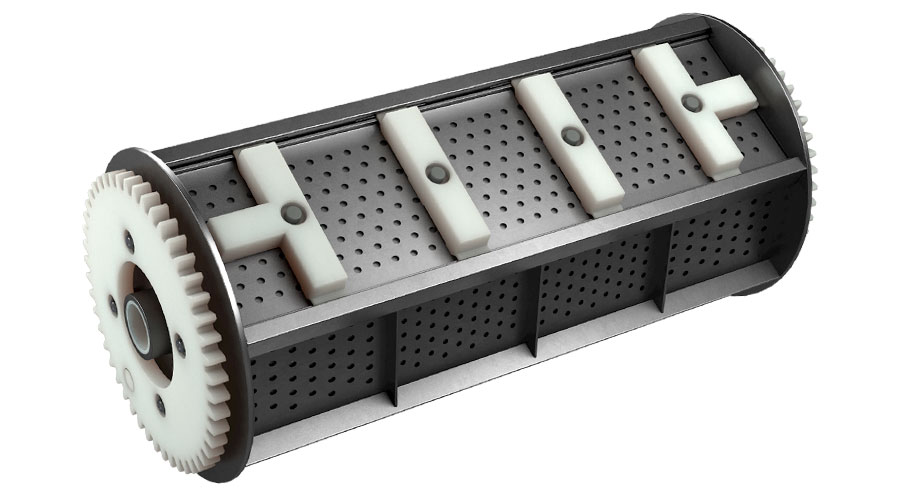

For electroless treatment processes, such as pickling, phosphating, degreasing, oiling or molykotizing, Linnhoff und Partner offers the right aggregate for every area of application. The barrel material used here is either stainless steel or PE1000; PP is also an alternative for smaller weights and temperatures. The choice of material depends on the process, maximum load, unit weight and temperature. It is often recommended to use a PE1000 barrel at temperatures up to 95°C and weights up to 1000 kg. The advantages here are the lower dead weight, quieter operation and gentle handling of the goods.

The sturdy stainless steel supports can be passivated, coated or rubberized. Here, too, high-quality SEW motors serve as the drive. All dimensions and equipment of the unit are, as always, designed according to customer requirements.

Barrel units for currentless processes

- Single barrel unit up to max. batch weight of 1000 kg

- Double barrel up to max. batch weight of 2x 500 kg

- Max. Temperature resistance: 135° C

- Alternatively made of high-quality stainless steel qualities or high-performance plastic

- In the plastic version more gentle on the material and quieter compared to stainless steel

- Dimensions according to customer requirements

- VA- carrier passivated (uncoated), coated or rubberized available

- Closure via rotary toggles or clamps

- Optionally available with tripping edge/partition wall