Good contact alone does not guarantee perfect current transmission. Other factors such as symmetrical busbars, clean contact surfaces and correctly dimensioned connection cables also play a major role. At Linnhoff and Partner you will find all necessary components for the equipment of your electroplating.

Connecting cables and conductor lines

We recommend using highly flexible connecting cables when connecting high current contacts or rectifiers. We produce these in different designs and cross sections according to your demands. These cables can be produced either of crimped copper braids and connecting flange or cable lug. According to your range of application and operation site the connecting cables are equipped with protective hoses of various materials like PVC, silicone or PUR before they are tightly crimped. We gladly advise you which cable suits your needs best.

Plastic receptions

Our plastic receptions are mainly manufactured from PE or PP. You can choose between our low-priced standard receptions or a version designed to your requirements.

Because of our 5-axis CNC centres we are also capable to manufacture complex shapes. A sample or sketch will do

in most cases.

„Beginners often overlook to keep the wires and contacts clean.

But this is of vital importance for the power circuit and thus for the plating process.“Dr. W. Pfanhauser, Galvanotechnik, 1928

Cleaning devices

Although there was already talk about this 90 years ago, it is still being neglected many times today. Only clean contacts can work efficiently.

To support your staff, we recommend cleaning devices at the rinsing tanks. These cleaning devices work independently of the plant operator. The contact surfaces of the carrier are cleaned during each cycle.

The simple and solid construction pays off here, too. The brushes can be changed individually. Cleaning devices can be optained for each type of contact (sword, pivot, prism, etc.) In most cases the cleaning devices can easily be changed for the existing plastic receptions.

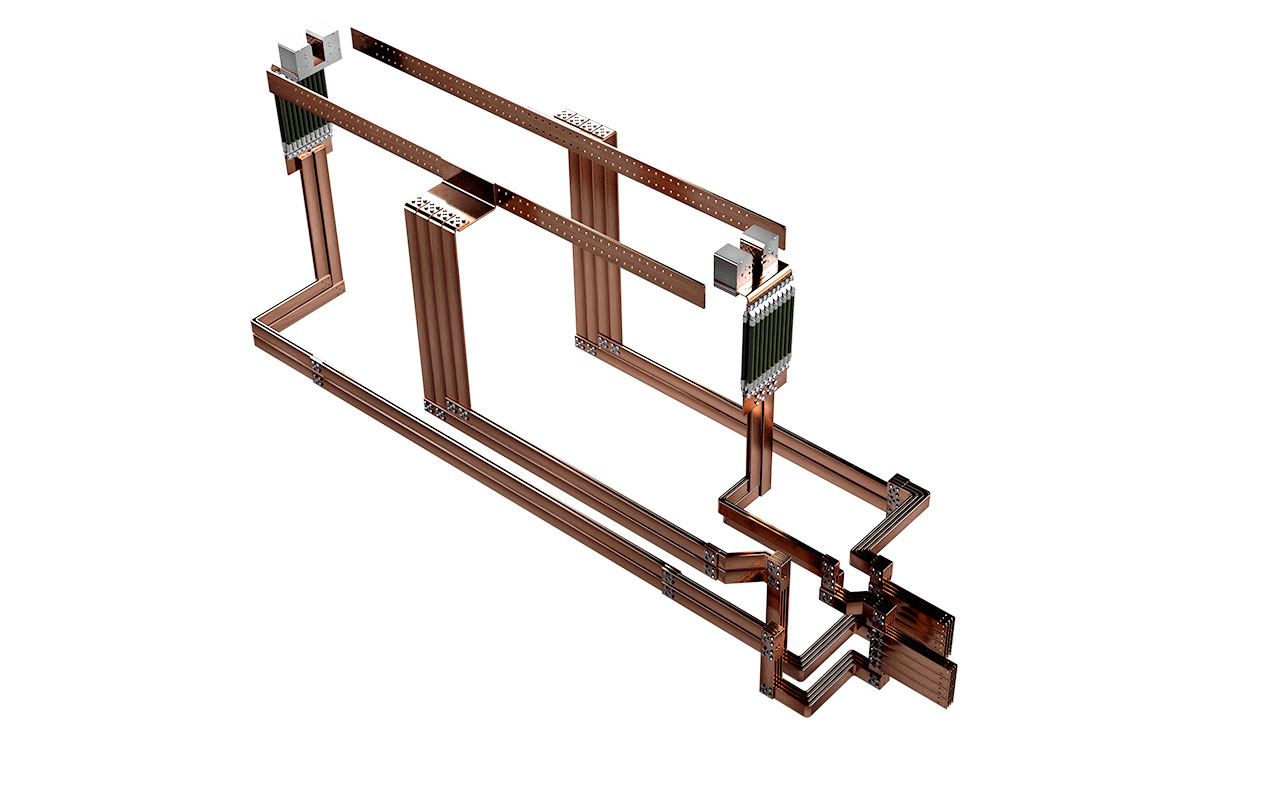

Copper rail connections

Making use of modern and professional piercing and bending technology we are able to produce and install copper rail connections on your premises. The raw material will be cut, pierced and bent on-spot to guarantee a precise adjustment to the operation site.

On request all copper rail connections will be delivered including assembly material, insulation and coverings. Normally it is also possible to modify existing connections or exchange individual segments without problems.

Together with our contacts or module components you will receive everything for the way from the rectifier to the reception from one provider. Thus a maximum compatibility can be expected.

Rack technology

Next to the classic high current contacts and barrel aggregates we also offer conventional components of rack technology. They comprise rack clips with pressure frame ‘Lipfix’, anode clips, rack fastener and holding blocks. We provide you with all necessary components for your carriers. You will also find special designs, small series and single units in our programme. Contact us and allow us to advise you.