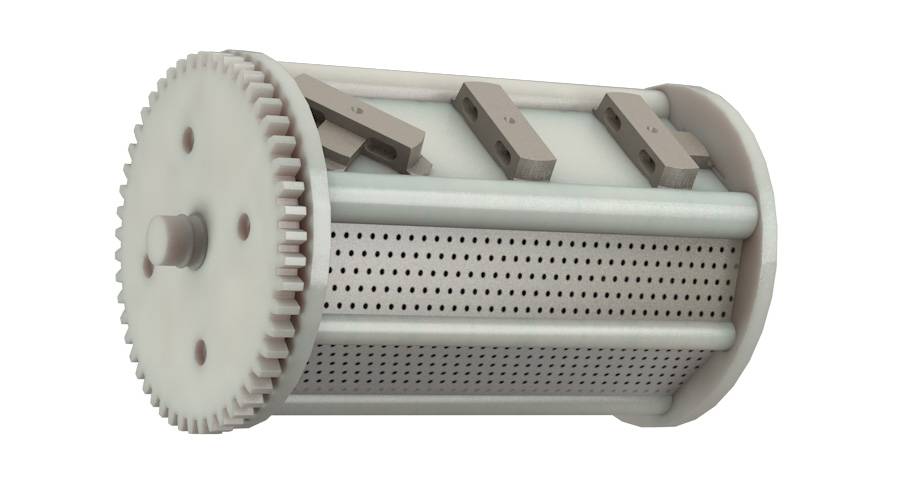

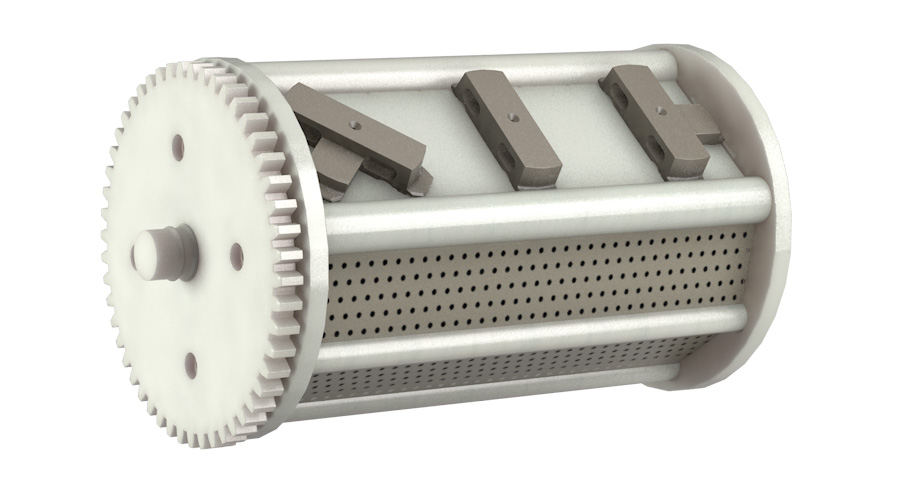

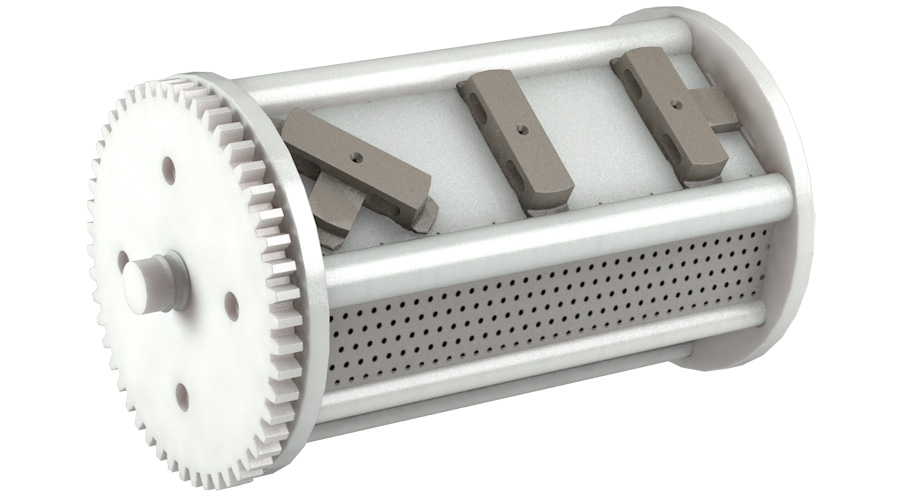

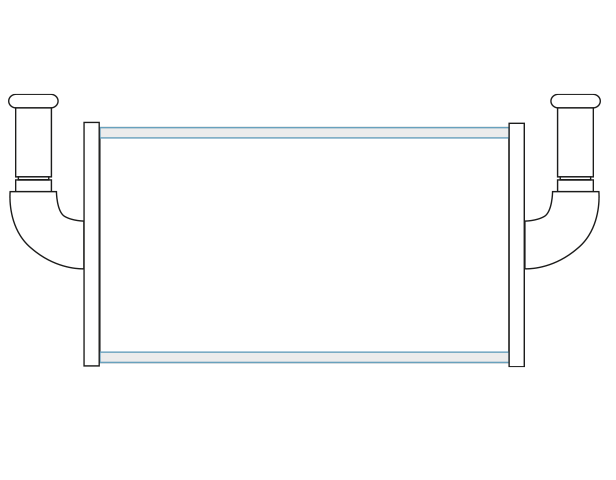

The attached cover provides optimal operational safety and easy handling. Position and shape of the cover are designed in such a way that not even the smallest particles can get between cover and barrel body.

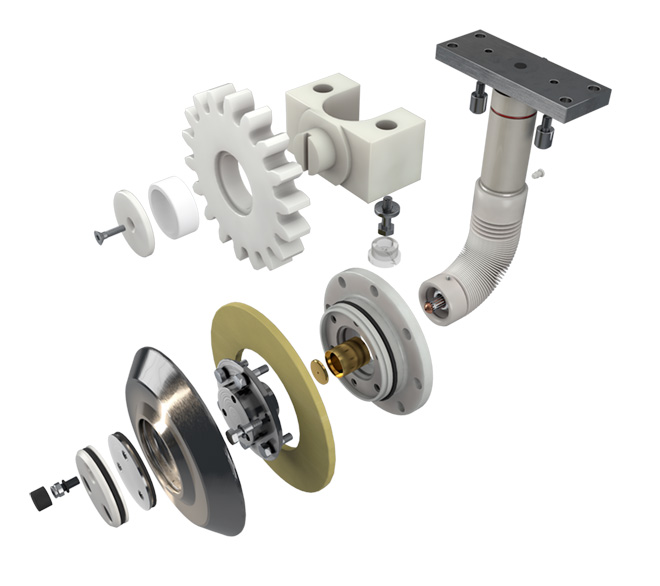

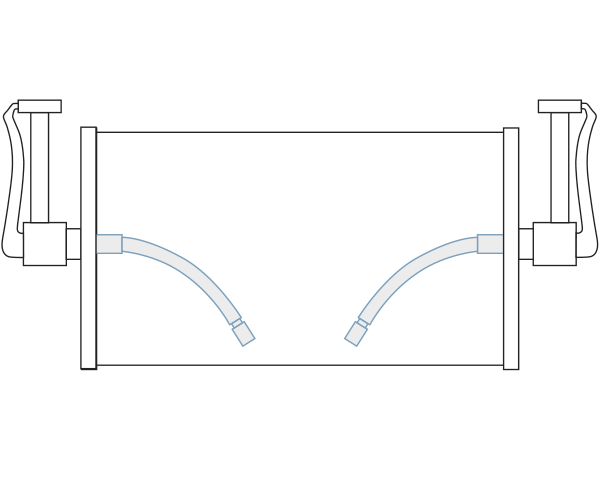

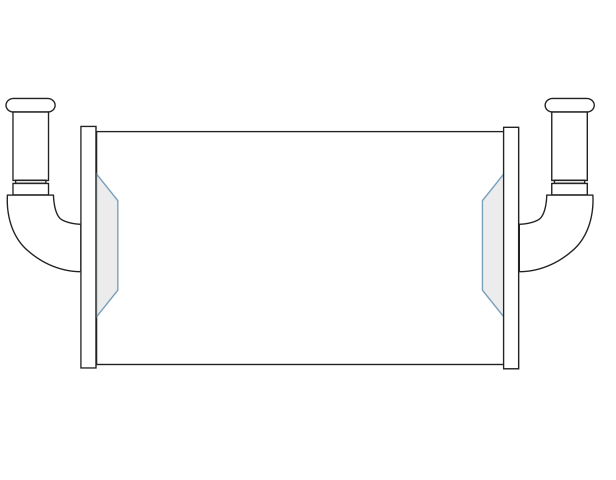

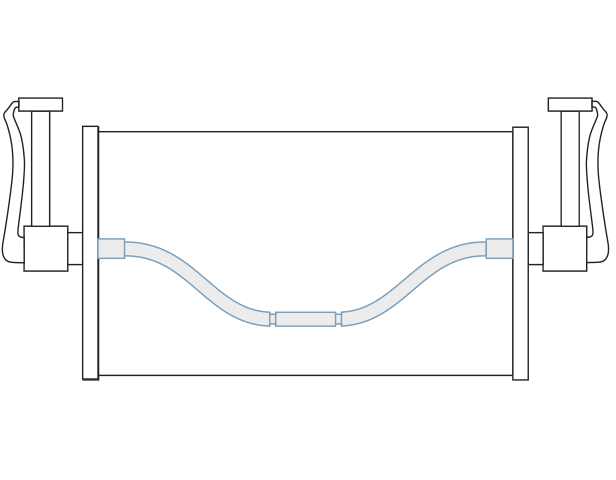

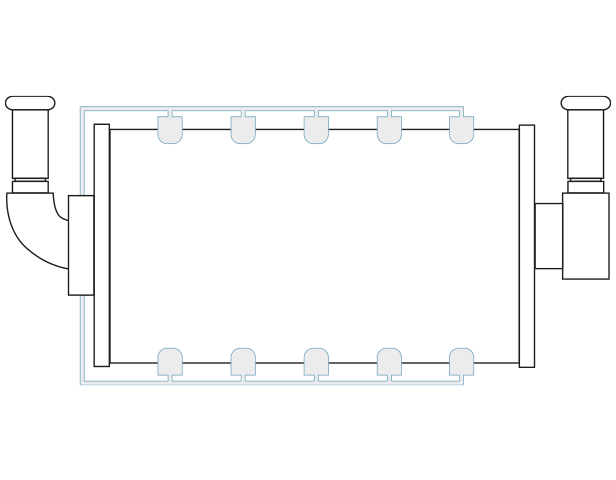

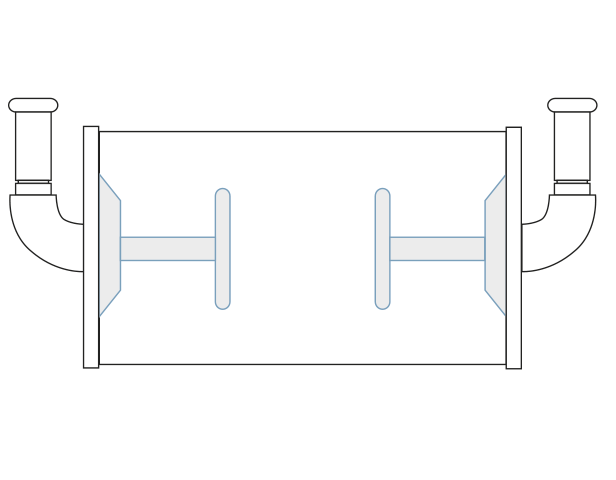

To transfer the plating current onto the product, different ways of contacting can be selected. One example is the classic cable contact, but also disc contacts, button contacts, pin contacts and many others are possible.

There is also the possibility to equip with a pendular unit, reverser unit or vibrating unit. To improve electrolytic exchange, an additional electrolyte injection pump can be added.

In short, the small barrel series is the optimal partner for rational plating. For electronic components, in the jewellery industry, for small series, subcontracted electroplating, research and development, the small barrel is a must.

You have batches of only a few grams, or very fine goods?

We can also do even smaller: our smallest barrel series.

This series includes mini barrel aggregates with a volume of approximately 300-1000 cm³. Specially manufactured mini drums are used here. By using different perforations a simple adaptation to the goods is possible. The specially designed bayonet lock guarantees a secure closure of the body. Let us advise you which system is best suited for you.