Efficient electropolishing is usually only possible to a limited extent, as small parts are laboriously threaded or plugged in by hand.

The electropolishing barrel offers the possibility of finishing goods with a maximum volume of 10 litres or a maximum weight of 30 kg to 100% in the same and highest quality. Careful processing using high-quality materials guarantees a long service life even under heavy loads.

For a quick and uncomplicated inquiry please use our form for barrel aggregates.

Solid, material-compatible system construction at the highest processing level with planned and finely ground seams in the interior area prevent the goods from sticking. The precisely fitting and tightly closing lid is characterised by both user-friendly operation and maximum operational reliability.

Only high-quality geared motors with motor protection are used for the drive. The infinitely variable speed adjustment allows speeds between 4-10 rpm, other speeds are also possible on request. The aggregate can also be equipped with a commuting function.

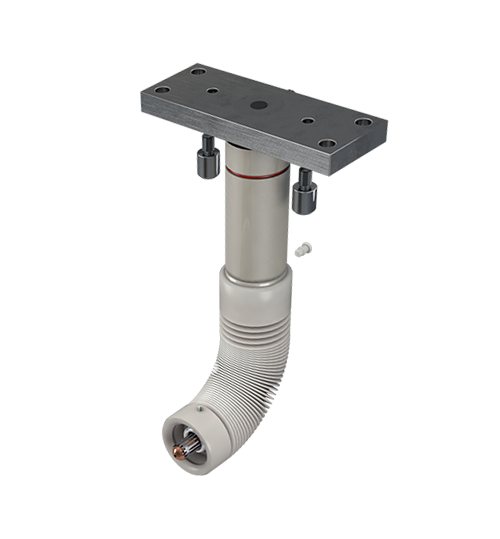

The current transmission and barrel storage is carried out by

two liquid-protected metal sleeve bearings.

The current is transmitted via these liquid-protected metal sleeve bearings. Thanks to the special contact fluid inside the bearing arm, the contact surfaces are cleaned and mechanical wear is minimized. From here, the power is fed directly into the double-walled barrel body and the double-walled central tube. The barrel body is made of titanium and stainless steel and is mounted short-circuit-proof. Optimum electrolyte exchange and minimized carry-over loss is achieved by smooth and gap-free transitions in conjunction with a sophisticated perforation system. One wall transmits the anode current, the other the cathode current.

The worldwide patent for this system was granted for the first time in 2003.

The electropolishing aggregate can in some cases be mounted under existing barrel carrier constructions. In contrast to our standard electropolishing aggregate, dimensional changes are no problem for us. We recommend the use of copper blade contacts in combination with a high-current surface contact to transfer the current. This pair has been shown to give the best results.

We would be pleased to check for you whether your goods are suitable for processing in the barrel; sampling is also possible without any problems in most cases.

Rely on efficient electropolishing in the barrel and save time and money.