Satellite plating aggregates

We plan, construct and produce barrel aggregates appropriate to your system so that your

machine can work without interruptions. Due to our perfect matching components we always

provide the correct solution for your applications. Manufacturing as single or double-barrel

aggregate or special construction.

For a quick and uncomplicated inquiry please use our form for barrel aggregates.

We supply all our barrel aggregats with various material options (stainless steel, titanium, high-performance polyethylene) and the individual assemblies can be combined for the respective application processes.

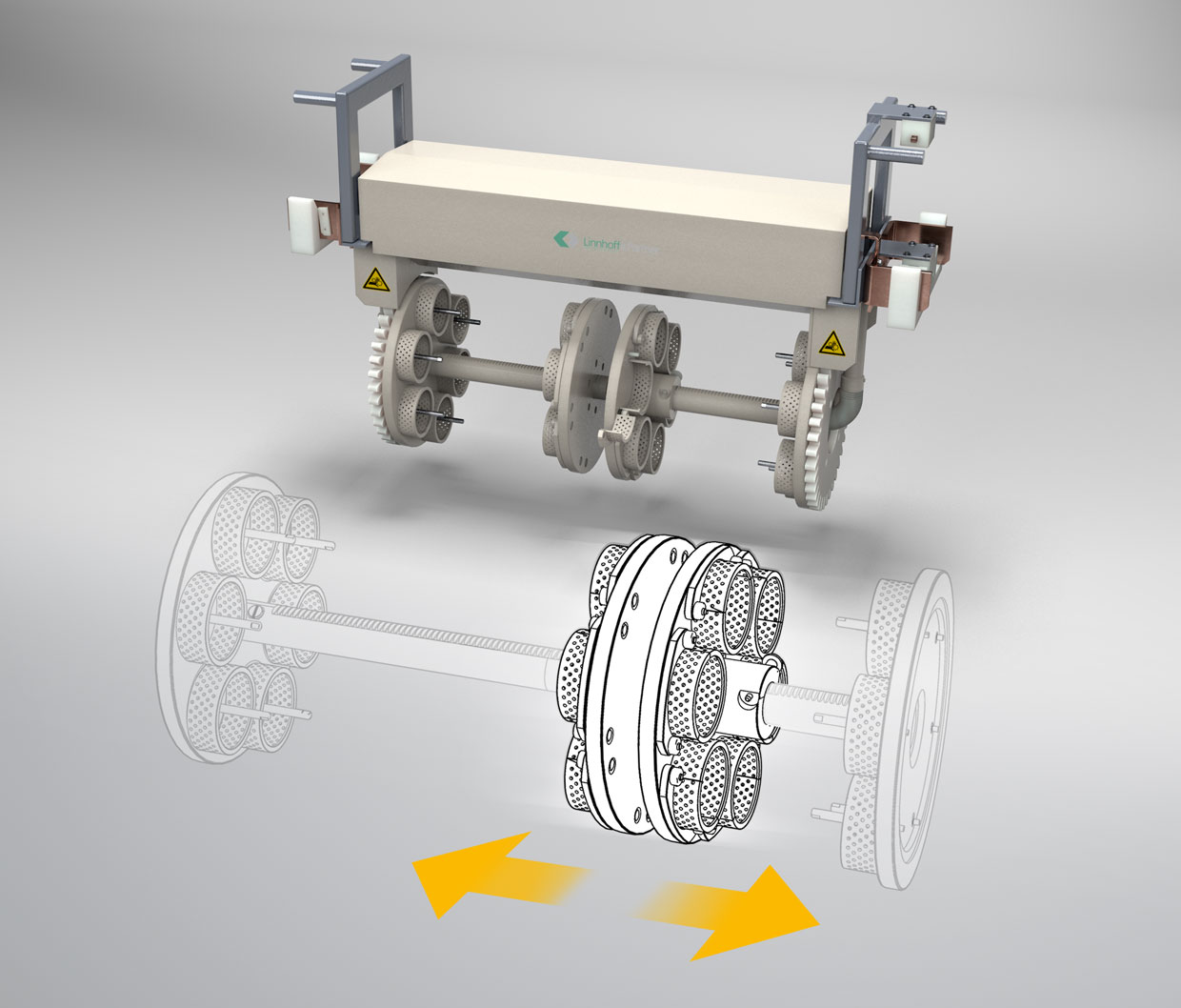

Satellite plating aggregates model range S200 and S600

This series was specially developed for bar-shaped “flat or round” material. The aggregates can be designed as single or double barrel aggregates. By using removable partitions, the barrel can be divided into several usable sections. In the S200 version, the partition walls are adjusted by means of a press pin, which results in a form-fit fixing. Batch weights of over 300 kg and lengths up to 2500 mm can be produced in these units. The barrel is made of PP or PPs. To minimize fluid carry-over, the entire body is welded.

The barrel concept allows best layer thickness distribution and drying in the barrel dryer. With the S200 variant, the generously dimensioned basket openings with 135° opening angle make it easy to fill the baskets. The special shape of the closure guarantees a gap-free and stable fit. Opposite is the basket, which is equipped with a 6 mm round perforation as standard. Wear rings are attached to the open end of the receptacles to extend the service life. For different goods, different geometries can be inserted into the basket opening, for example hexagonal or quadrangular. The baskets are equipped with a round geometry as standard.

The mounts of the larger S600 variant consist exclusively of strong wear rings. They are held by steel-reinforced supports to support heavier weights. The length is adjusted by a rack on the barrel carrier. This means that even large adjustment ranges can be made easily and reliably.

For the drive of our bar barrel units we recommend at least the use of a 2-stage geared motor to be able to adjust the speed. Motors with continuously variable transmission are also possible and offer the optimum solution, especially for very different goods.

For contacting, pin contacts are used in both versions, which are located centrally in the receptacles. These contact pins can be designed on one side, on both sides or continuously.