Equipment and spare parts

In the simplest case, barrel aggregates consist of barrel carrier, barrel, drive and contact unit. For special applications we offer a range of additional equipment, such as electrolyte injections or commuting devices. This applies not only to new plants, but also to existing ones. Whether and which equipment is required depends on the process and the goods to be coated. Let us advise you.

Contact cable

Our durable contact cables are made of PUR sheathed cable as standard. The cable specially manufactured for us is available in various diameters and cross-sections up to 240 qmm. Special applications such as PVC, silicone and neoprene cables are also possible. Our “contact bulbs” are available in steel, brass, stainless steel or special materials such as titanium or copper. The design can be hollow, screwable, continuous or in other special forms. Let us advise you individually and increase the service life of this parts.

Are you looking for spare parts for your aggregates, contacts or other plant components? Then you’ve come to the right place. We manufacture and procure spare parts of all kinds. You will find any spare part you need from us. We are happy to help you with the selection or procurement. Production according to sample is also no problem for us. Please contact us, we will help you.

Once the barrel is immersed in the bath, it is difficult to tell if it is really turning or not. We use various systems to monitor engine rotation. Mechanical solutions are also conceivable. In most cases, the rotation of the motor gear wheel is monitored. The most common cause of malfunction is dirty or worn motor current contacts, so monitoring the phases and regular cleaning of the motor current contacts is usually helpful in most cases. Replacing the same system with an improved one can also fix the problem and make monitoring unnecessary.

In some cases, the electrolyte in the barrel is depleted, which can be due to a very small perforation or a very fast deposition. In order to transport fresh electrolyte into the barrel, we work with 2 types of electrolyte injection. Option 1 is possible by using a pump on the unit. This sucks in the corresponding medium and presses it through pipes into the barrel body. Option 2 is the use of a bottom adapter on the tank bottom. Here you can work with an external pump.

The choice depends on various factors, such as space, number of baths and number of units. We are happy to help you make the right choice.

In special cases, continuous rotation of the barrel can cause damage to the goods. Here it makes sense to let the barrel oscillate. By changing the direction of rotation, the fabric is treated particularly gently. Commuting can be done either over time or along the path. The controller can be installed either in the aggregate or, for smaller aggregates, as an external unit in front of the motor power contact. For instruments in the laboratory or in manually operated electroplating shops, we also offer this controller as an add-on device with connection jack.

Perforations

The quality and effectiveness of barrel electroplating is considerably depending on the kind and size of the perforation. We offer a wide range of different perforations in order to choose the perfect one for your applications.

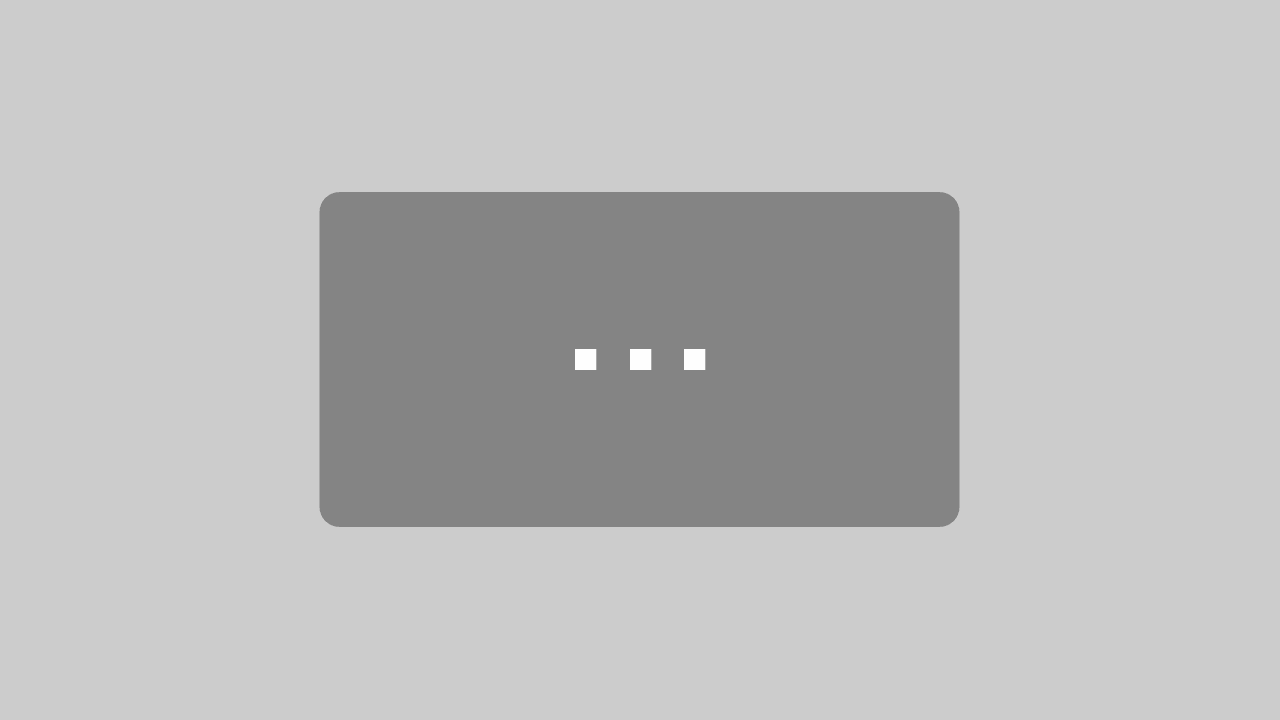

Round perforation

The outstanding quality of the barrel material allows an extremely close perforation. Inner and outer counterbores resp. milled recesses support the electrolytic exchange, reduce the drop in voltage in the wall, reduce carry-over losses and prevent flat components from adhering to the wet barrel.

Special features:

- very close hole distance

- counterbores on both sides

- as for sticky components overlapping counterbores can be milled

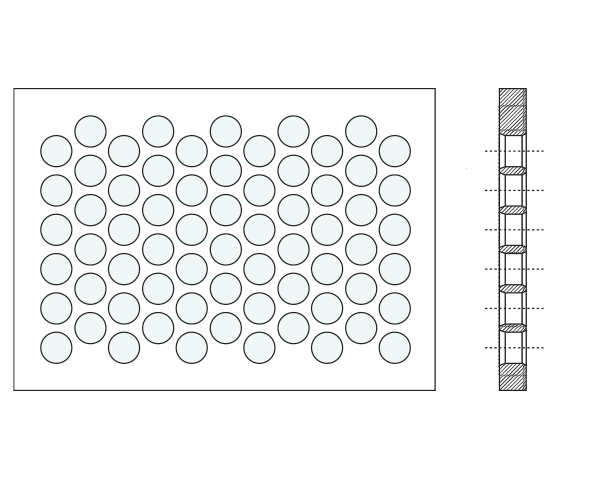

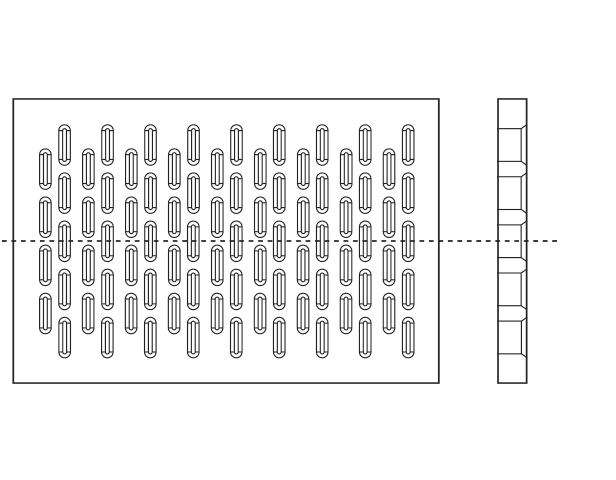

Slot perforation

Due to the overlapping milling of the slots the stability of the individual plates remains intact. The outstanding quality of the barrel material allows the very close perforation, therefore even higher component weights do not present a problem.

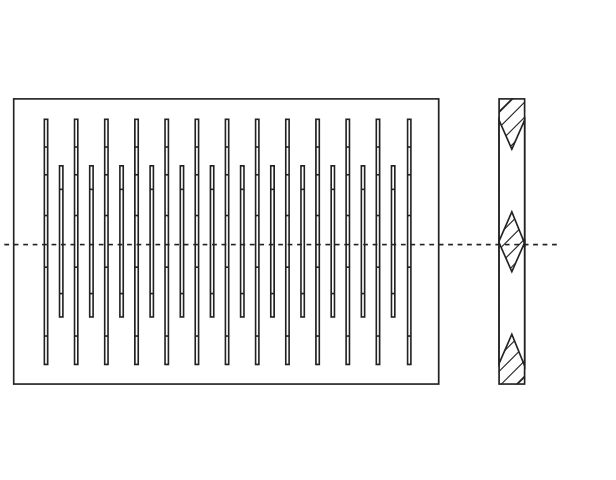

Half-moon perforation

Among all kinds of perforation the half-moon perforation offers the widest range of products (nails, screws, coins, punched and bent components, and many more).

A considerably larger perforation space of up to more than 30 per cent (e.g. in contrast to an equivalent round perforati-on) guarantees a better electrolytic exchange. By means of special milling tools plates of up to 20 mm can be easily perforated in the half-moon version, thus resulting in con-siderably longer service lives. The conical form on the outsi-de enables both a quick penetration and a quick draining of the electrolyte.

Long-slot perforation

Similar to the design of the half-moon perforation, the long-slot perforation offers the same advantages. It has been developed to replace the sawn slot perforation as the dimen-sionally stable geometry avoids a widening of the perforation.

Filter plugs

Our perforated plugs can be used universally, especially for the finest goods. Very small perforations cannot be machined, therefore it is recommended to use perforation plugs for perforations smaller than 1 mm.

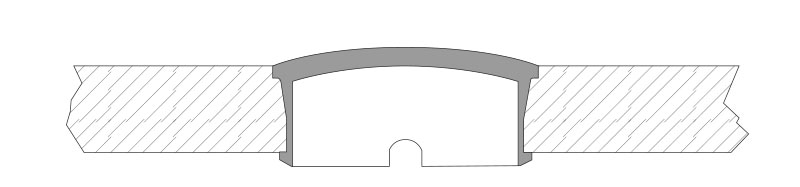

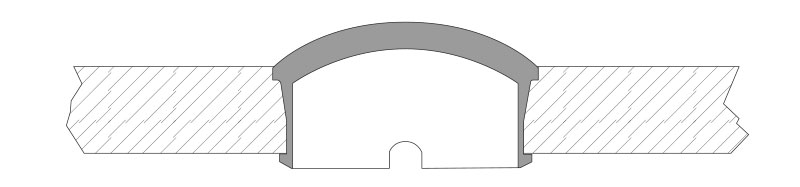

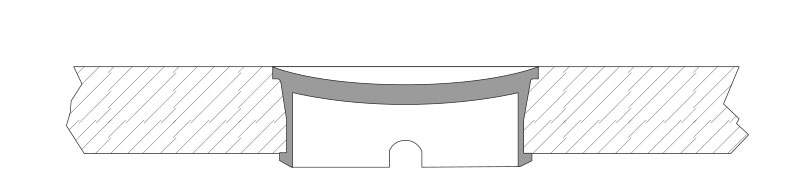

The plugs can be replaced. After removal, the perforated plug is damaged and cannot be reused. The special design of the perforated plugs (concave/convex) often helps to solve problems with adhesive parts.

Standard model

Convex model

Concav model

A-filter plug product range ∅ approx. 40 mm

material: PP

| Pos. | name | artikel number |

| 1 | 0,25 slot | 90000100 |

| 2 | 0,4 slot | 90064500 |

| 3 | 0,6 slot | 90117800 |

| 4 | 1,3 slot | 90018400 |

| 5 | 1,3 slot concave | 90081800 |

| 6 | 1 x 1 | 90000400 |

| 7 | 1,75 x 1,75 | 90070300 |

| 8 | 2 x 2 | 90000500 |

| 9 | 2 x 2, convex | 90000700 |

| 10 | 2 x 2, concave | 90037900 |

| 11 | 3 x 3 | 90000810 |

| 12 | 3 x 3 convex | 90000900 |

| 13 | 8 x 8 convex | 90018300 |

| 14 | 0,25 slot witht 2 x 2 raster | 90000300 |

| 15 | half-moon plug 1,3 mm | 90823700 |

E-filter plug product range ∅ approx. 23 mm

material: PP

| Pos. | name | artikel number |

| 1 | 0,25 slot | 90001300 |

| 2 | 0,4 slot | 90019500 |

| 3 | 0,4 x 0,4 | 90117600 |

| 4 | 1 x 1 | 90017100 |

| 5 | 1 x 1 convex | 90001400 |

| 6 | 2 x 2 | 90098900 |